HOOKS

Lifting hooks are the hardware of choice for quick, non permanent connections to a lifting point. Typically attached to the end of a sling, hooks come in a wide variety of sizes and styles.

I&I Sling maintains stock of the most popular sizes and styles, including eye hooks, swivel hooks, grab hooks, Shur-loc hooks and snap hooks. All our hooks are tested from the manufacturer and rated and marked in compliance with ASME B30.10.

Types of Hooks

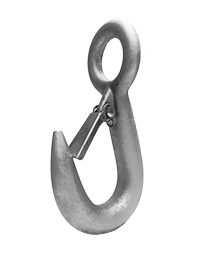

Eye sling hooks are the most common type and are intended to be permanently installed onto your sling. They come in both carbon and alloy (allowing more capacity for the same size) and feature a standard throat opening that can allow for easy connection and disconnections to the load.

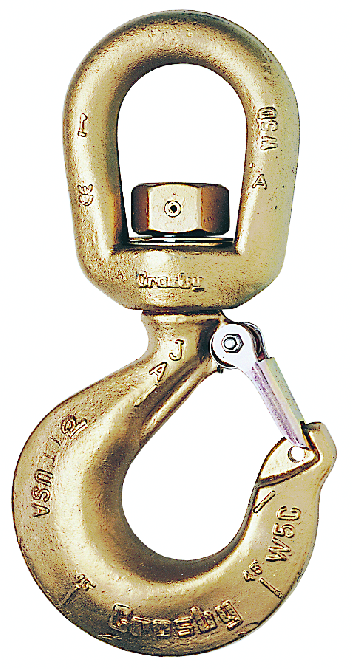

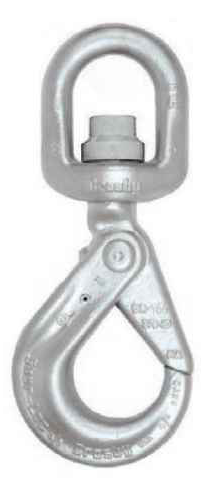

Swivel hooks give the rigger the ability to rotate the hook. There are two types of swivel hooks: a standard (positioning) swivel hook and a swivel hook with bearings. Standard swivel hooks are designed to be rotated before load is applied. A swivel hook with a bearing can be rotated while both under load or when no load is applied to the hook which makes it very versatile. Swivel hooks are a great tool to easily position the sling and prevent twisting of the rigging.

Self locking hooks or Shur-Loc hooks come with a latch that locks in place. The latch is very durable and is almost impossible to open until the load is released. These hooks are available in eye, clevis, swivel and swivel with bearing.

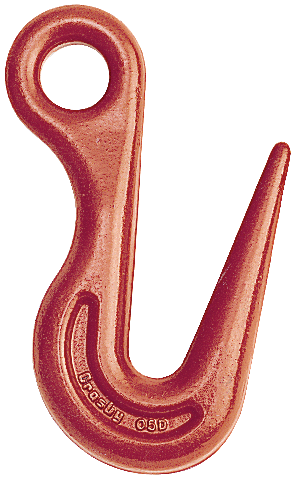

Choker or grab hooks are typically used with chain and allow the chain sling to be grabbed and either choked or shortened. Available in two different types - standard and cradle and in both eye and clevis. Cradle grabs are the choice if you intend to shorten your chain with it as it allows you to achieve the full working load - performing shortening with a standard grab hook requires a 20% reduction in capacity.

Rigging hooks can be installed onto your wire rope, chain, roundsling or web slings. Extending the life of your sling and providing a better connection to your lift. We recommend utilizing latches with almost all hooks. I&I Sling is a full service sling repair center, which enables us to replace or install latch kits onto your hooks, offering the peace of mind of additional safety features while also extending the life of your existing hooks.

There are many other types of hooks we can provide including drum/barrel hooks, sorting hooks, J-hooks and foundry hooks. Reach out to your Product Advisor to find the hook that fits your application.

Frequently Asked Questions

What is an eye hook and where is it used?

An eye hook is a lifting hook that features a closed eye at the top for direct connection to a sling, shackle, or hoist hook. The eye provides a fixed attachment point, allowing the hook to be installed permanently or semi-permanently within a rigging assembly. Eye hooks are commonly manufactured from forged alloy steel and are rated for overhead lifting applications when used within their working load limits. Eye hooks are used in rigging systems where a secure, non-slipping connection is required. They are commonly found on wire rope slings, chain slings, synthetic sling assemblies, hoists, and lifting devices. Eye hooks are preferred in applications where the hook will remain attached to the rigging, where rotation is not required, or where space limitations prevent the use of larger hardware such as shackles or swivels.

How does an eye hook differ from a swivel hook?

An eye hook differs from a swivel hook in how it handles load movement and rotation. An eye hook has a fixed connection point, meaning the hook does not rotate once installed. This makes it suitable for straight, controlled lifts where load rotation is not expected. A swivel hook, on the other hand, is designed to position or rotate. Swivel hooks with bearing can rotate under load, allowing the hook to align with the load as it moves or turns. Swivel hooks help reduce twisting in chains or slings and are commonly used when load orientation may change during lifting. Both must be properly rated and installed for safe operation.

What size eye hook should you choose for a given load or application?

The eye hook should exceed the share of the load to the leg that it is attached. If it is being used to carry the full load, it must exceed the weight of the load and the rigging. Some things to consider are the dimensions of the hook. Alloy Eye hooks will be smaller than Carbon Eye hooks and depending on what type of rigging you are utilizing, D/d Ratio may have to be taken into consideration if the hooks a smaller in dimension.

What safety considerations are there when using eye hooks in rigging?

When using eye hooks in rigging, the primary safety consideration is ensuring the hook is used within its rated working load limit and only in approved lifting applications. The hook must be properly sized for the load and compatible with the connecting hardware to prevent side loading, point loading, or binding in the eye. Eye hooks should always be loaded in line with the hook bowl and never subjected to angular or off-axis forces unless specifically rated for it.

Before each lift, the hook should be inspected for cracks, deformation, excessive wear, throat opening, bent tips, or damage to the eye. Hooks with safety latches must have fully functional latches, although the latch should never be considered load-bearing. Eye hooks should not be twisted, shock loaded, or used to drag loads. Any hook showing signs of overload, altered shape, or illegible identification must be removed from service immediately. few considerations that must be looked at when using eye hooks:

- Size of the hook with the type of rigging being used – Regarding D/d Ratio or the size of eye that will be placed into the hook

- Type of latch on the Hook – Positive, Standard, or no latch due to hazards hooking or unhooking the load for the rigger

- Material of the Hook – Drop Forged or Alloy

- Does it need to Swivel? And if it does, does it need to swivel under load?

- What type of environment will the hook be used in