TRI-FLEX SLINGS

FEATURES

Flexible

Abrasion Resistant

Low Stretch

Made In USA

Low D/d

Low Length Tolerance

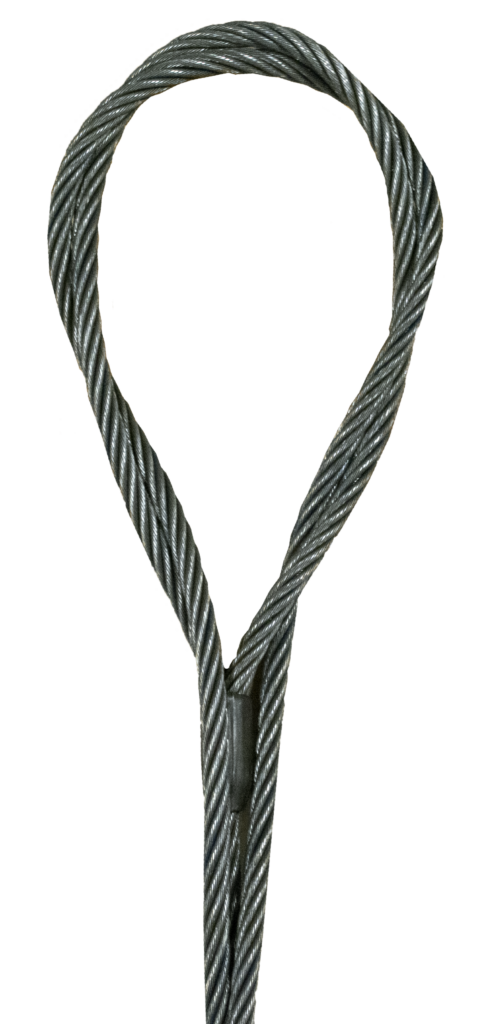

Tri-Flex Wire Rope Sling

The Tri-Flex wire rope sling is composed of 3 parts of wire rope and mechanically spliced to create a wire rope sling that is flexible, rated for high capacities, and has the ability to be used with small hardware without loss of capacity (low D/d). Popular among steel erectors, general construction and millwrights, Tri-Flex slings are the preferred replacement for traditional wire rope slings. Available in a wide range of sizes and capacities from ½” to 5” finished diameter and up to 145 tons, Tri-Flex multi part wire rope slings can meet your job requirements.

GATOR-LAID

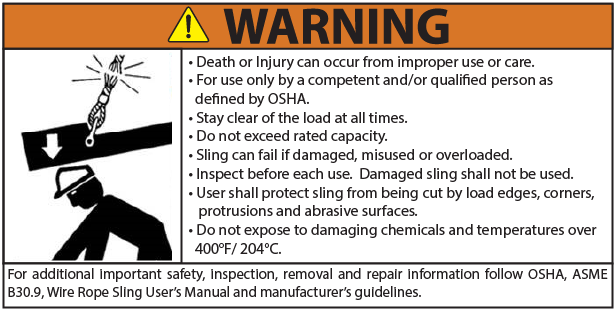

USE AND CARE

TWIN-PATH SLINGS

Quality Manufacturing

I&I Sling has been fabricating Tri-Flex slings for 50 years and the product is custom built to order by an experienced fabricator at your local I&I branch. High quality domestically produced wire rope is used in the manufacturing of Tri-Flex slings at I&I Sling. With a 5 to 1 design factor, Tri-Flex slings are fully compliant with ASME B30.9 and can be proof tested to 2 times rated capacity upon request. They are able to be constructed in matching sets or within +/- the finished diameter of your required length.

Great Flexibility and Reduced D/d

The inclusion of 3 individual parts of wire rope transforms a traditional single part wire rope sling into a multipart wire rope product that is significantly more user friendly and versatile. Large diameter wire rope can be cumbersome and expensive. Utilizing 3 smaller diameter ropes does not only achieve greater flexibility, but it also reduces the overall cost of the sling when compared to large single part wire rope slings. An added benefit of using 3 smaller diameter ropes over a single large diameter wire rope is a greatly reduced D/d ratio. Requiring only a 1.5:1 D/d in the eye and 5:1 D/d in the body. Reduction considerations for working load limits with your wire rope sling becomes less of an issue when utilizing 3 part wire rope slings.

| Finished Diameter | Component Parts | Vertical Rated Capacity (tons) | Choker Rated Capacity (tons) | Basket Rated Capacity (tons) | Weight per Foot (lbs.) |

| 1/2" | 1/4" | 1.7 | 1.3 | 3.4 | 0.44 |

| 5/8" | 5/16" | 2.6 | 1.9 | 5.2 | 0.68 |

| 3/4" | 3/8" | 3.6 | 2.7 | 7.2 | 0.99 |

| 7/8" | 7/16" | 4.9 | 3.7 | 9.8 | 1.33 |

| 1" | 1/2" | 6.4 | 4.8 | 12.8 | 1.75 |

| 1-1/8" | 9/16" | 8 | 6 | 16 | 2.24 |

| 1-1/4" | 5/8" | 9.9 | 7.4 | 19.8 | 2.73 |

| 1-1/2" | 3/4" | 14 | 10.5 | 28 | 3.9 |

| 1-3/4" | 7/8" | 19 | 14.3 | 38 | 5.4 |

| 2" | 1" | 24.8 | 18.6 | 49.6 | 7 |

| 2-1/4" | 1-1/8" | 31.2 | 23.4 | 62.4 | 8.9 |

| 2-1/2" | 1-1/4" | 38.4 | 28.8 | 76.8 | 10.9 |

| 2-3/4" | 1-3/8" | 46 | 34.5 | 92 | 13.3 |

| 3" | 1-1/2" | 55 | 41.2 | 110 | 15.8 |

| 3-1/4" | 1-5/8" | 63.4 | 47.6 | 126.8 | 18.5 |

| 3-1/2" | 1-3/4" | 73 | 54.8 | 146 | 21.5 |

| 4" | 2" | 95 | 71.2 | 190 | 28 |

| 4-1/2" | 2-1/4" | 118 | 88.5 | 236 | 35.6 |

| 5" | 2-1/2" | 145 | 109 | 290 | 44 |

Tri-Flex with Cable Laid

For more flexibility and an even better choker, Tri-Flex slings with cable laid can be your solution. Combining the design of the Tri-Flex sling with the flexibility of cable laid wire, this solution provides one of the most flexible steel slings available. Commonly used in transportation and distribution, Tri-Flex slings with cable laid wire are excellent at setting and removing utility poles or other applications that utilize choker hitches.

| Finished Diameter |

Component Parts |

Vertical Rated Capacity (tons) |

Choker Rated Capacity (tons) |

Basket Rated Capacity (tons) |

| 1/2" | 1/4" | 1.3 | 0.9 | 2.6 |

| 3/4" | 3/8" | 2.7 | 2 | 5.4 |

| 1" | 1/2" | 4.6 | 3.4 | 9.2 |

| 1-1/4" | 5/8" | 7 | 5.2 | 14 |

| 1-1/2" | 3/4" | 10 | 7.5 | 20 |