LIFTING BEAMS

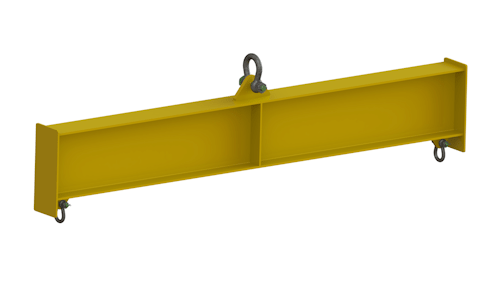

Lifting beams are the ideal alternative to a spreader beam and allow for low headroom situations or when you need the beam to support the load. Typically used in indoor applications, the top of the lifting beam usually has a single attachment point centered on the top side of the beam for connecting your lifting device. This design of the lifting beam is for even loading that is spread out across the span of the beam. However, some lifting beams may have multiple bails in order to engage two crane or hoist hooks. When selecting your lifting beam it is important to review your lift details with your Product Advisor to determine the ideal span and capacity of your beam.

There are at least two lifting lugs on the underside of the beam that attach to and support the load via a hook or sling. This allows for great flexibility in your rigging attachments. Twin-Path slings are a great choice, for the bottom rigging of your lifting beam, due to their lightweight, flexibility and overload features.

Lifting beams do not require top rigging like spreader beams because they are designed to convert lifting loads into bending forces on the beam. This is great for low head room situations and for lifting loads that require support, such as steel plates or bundles of piping.

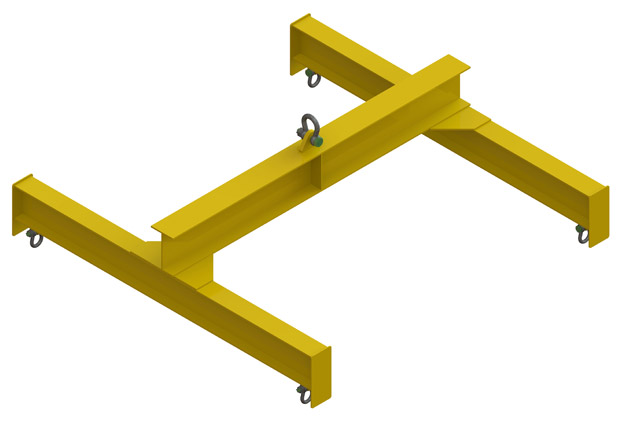

We can advise on the safest type of rig design for a particular application, and check the stability of the load, and can design Lifting Beams and Frames to suit more complex rigs, below are some examples.

- Multiple connection points to suit different spans/sizes

- Additional adjustability to accommodate loads with offset centers of gravity

- ‘Inverted’ Lifting beams: Tandem Lifting Beams where there are two top lifting points and one central bottom lifting point e.g. when turning two crane hooks into one central lifting point

- Beams/Frames with shackle/crane hook/direct attachment to the load

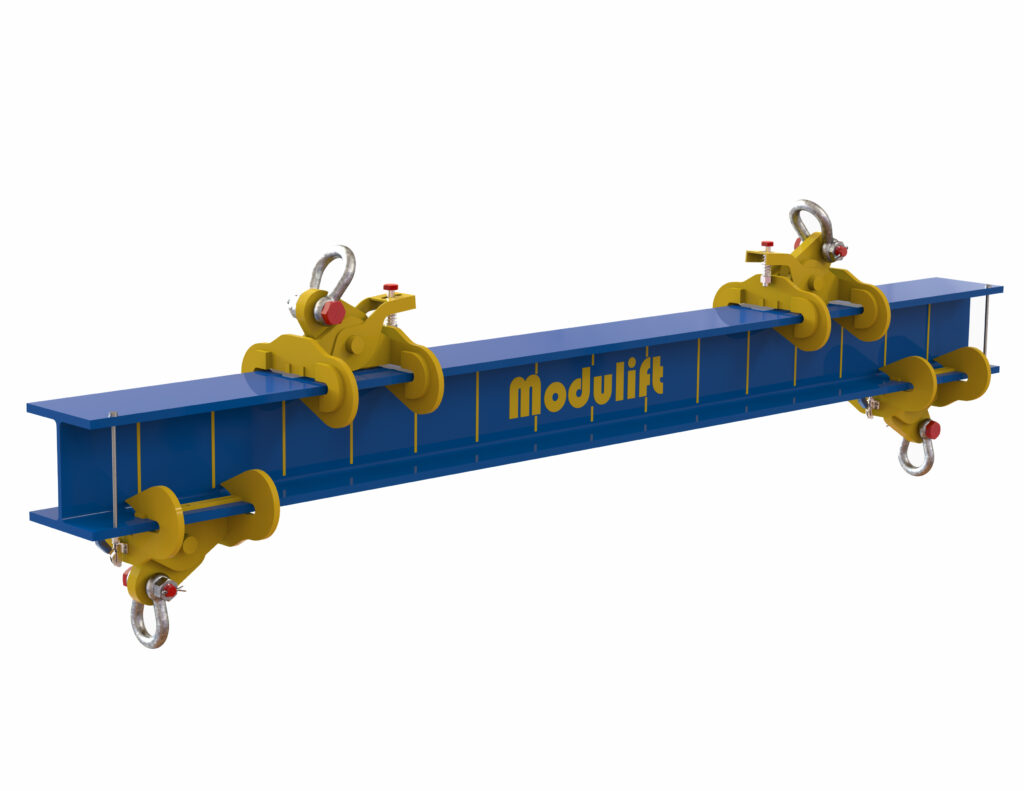

I&I Sling supplies innovative lifting beams which allow for the lifting points to be repositioned. The Modulift Adjustable Lifting/Spreader Beam (MOD CLS) can lift up to 27t and has a new and improved clamp system, tested to the highest standards, enabling safe lifting from multiple points.

Main benefits are:

- Spans of up to 16m and capacities of up to 27t depending on configuration

- Adjustable lifting points and low head room capability

- Easy to convert between a lifting beam and a semi spreader beam

Knowing The Difference Between Spreader & Lifting Beams

Lifting beams are used when available headroom is not sufficient for top rigging. Lifting beams must be designed structurally larger than spreader beams to adequately handle load stress. Spreader beams with top rigging are smaller because most load stress is absorbed by the rigging. This differentiation is critical in order to properly specify the equipment required.

Contact your I&I Sling Product Advisor to assist you with choosing the correct beam for your application.