INSTRUCTIONS FOR CARE, USE,

INSPECTION, AND REPAIR

Wire Rope Sling Use and Care

CARE

- Store in a dry, clean area away from chemicals, dust, grit or elevated temperatures.

USE

- Check weight of load.

- Check sling rated load for type of lift & angle of loading.

- Sling shall not be twisted, tied into knots or joined by knotting.

- Be sure that the load cannot cut the sling during the lift by padding corners, edges, protrusions or abrasive surfaces; use materials of sufficient strength and thickness.

- If the hook is attached to the sling, center load on base (bowl) of sling hook unless sling hook is designed for point loading.

- Balance load.

- Maintain load control.

- Avoid jerking the load.

- Be alert for snagging of load.

- Avoid dragging sling over rough surfaces and from under the load.

- Choker hitch must choke on sling body, never on a splice or end fitting.

- Stand clear of load at all times.

- Persons are not to ride on sling or load.

- For use in abnormal conditions of heat, cold, chemical activity, consult the manufacturer.

- Restrict use to temperatures below 400 ℉ (fiber core wire rope below 180℉) and above -40℉

- Important: A single leg sling with hand tucked splice can unlay and drop the load if allowed to rotate during a lift. Always use a tag line.

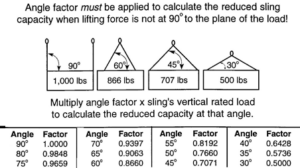

LOAD ANGLE CHART

INSPECTION

INSPECTION

- Before use: Look for rope distortion, kinks, cut or broken strands, corrosion, heat damage, birdcaging, or crushing. Look at the end attachments for cracks, wear or deformation, hooks with twists or a throat opening increase. Look for broken or missing wires.

- For strand laid and single part slings, no more than 10 broken wires in a 1 lay or 5 in 1 strand lay in 1 lay.

- For cable laid and braided broken wire inspection criteria, consult the manufacturer. If an inspection reveals that such wear or damage is present, replace the sling. Frequent inspection is done by the person handling the sling before each use and must include all of the Before use Periodic inspections must be recorded at least annually for normal service, quarterly or more frequently if in severe service or nearly constant use. Periodic inspections are performed by a designated person who records the observed condition and determines when further use would be hazardous.

REPAIR

- Any hazardous condition disclosed by an inspection shall require replacement of the wire rope sling. Repair is not an option when damage/wear seriously reduces the sling’s capacity.

Because of the greatly reduced lifting capacity, use extra when the horizontal lift angle is less than 45° and do not make lifts of less than 30° load angle. Example: A sling rated at and lifting 1,000 pounds will be damaged – and could break suddenly – when the lifting angle is less than 30o at which angle the sling’s capacity is reduced to only 500 pounds. Important: Use a longer sling to increase the angle which will also increase the allowable capacity.

For choker hitches, the lifting capacity is reduced by 25% or more, depending on the capacity