CROSBY SHACKLES

Shackles are most commonly used as connection hardware. I&I Sling stocks and supplies many different types of shackles. This includes Screw Pin Anchor, Bolt Type Anchor, Chain, Wide Body for improved D/d Ratio, Long Reach and wide mouth shackles.

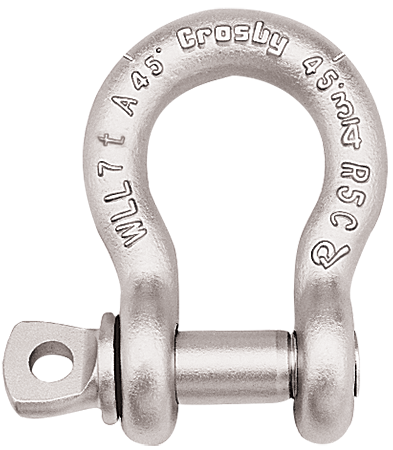

Screw pin shackles have a pin which screws in the ear of the shackle. This makes them great for quick load hook up and tear down.

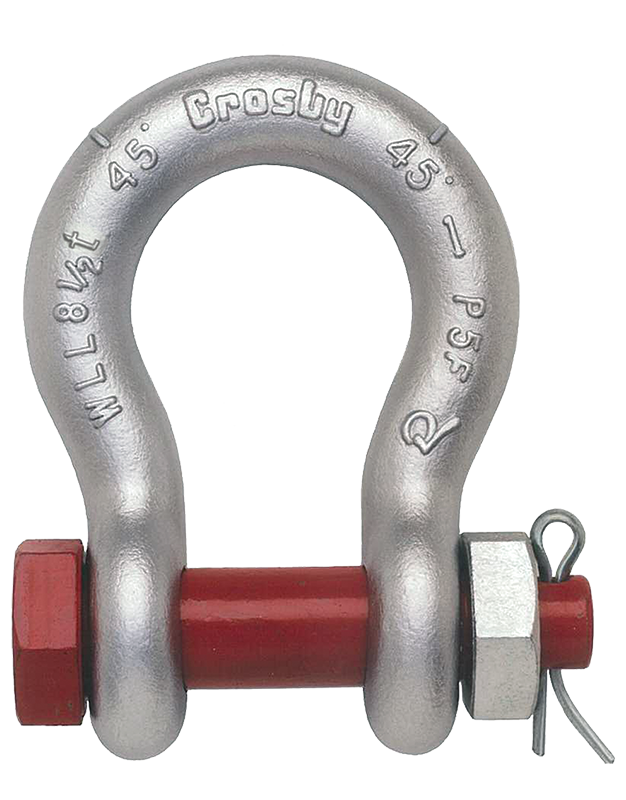

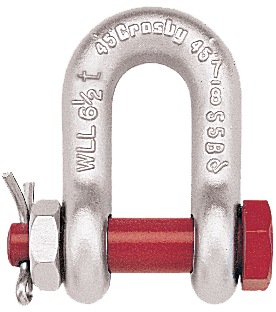

Safety bolt shackles have a bolt pin that goes through the ears and are secured with a nut. A cotter pin can be put through the nut end to make it the most secure shackle pin style.

Round pin shackles are simple and consist of a pin that slides through the shackle ears and are secured with only a cotter pin. Because of this round pin shackles should never be used in rigging applications to gather multiple sling legs or where side loading conditions may occur.

In most cases shackle size is determined by the diameter of the steel in the body (bow) of the shackle. Anchor & Chain Shackle size is determined by the bow diameter. Special design shackles (i.e. Wide Body) sizes will normally be determined by its pin diameter. Synthetic flat shackle sizes are determined by the width of the flat surface that incorporates synthetic web and roundslings. Shackle bodies have durable markings, by the manufacturer, to show: Manufacturers name or trademark, Size and Rated load. Reach out to an I&I Sling Product Advisor to assist with choosing the correct shackle for your job.

At I&I Sling, we are proud to manufacture the highest quality slings at our locations right here in the US. Furthermore, we are authorized distributors of American-made lifting equipment and rigging supplies from industry leaders such as the Crosby Group. For over a century, the Crosby Group has been a world leader in rigging, lifting, and material handling hardware, It is our pleasure to be your first call for Crosby Group shackles and other lifting equipment.

Frequently Asked Questions

What is a Crosby shackle?

A Crosby shackle is a piece of rigging hardware forged from steel and produced by The Crosby Group, one of the most recognized names in rigging hardware. Shackles are used to connect synthetic fiber slings, wire rope slings, chain slings, or other hardware to a load or hook.

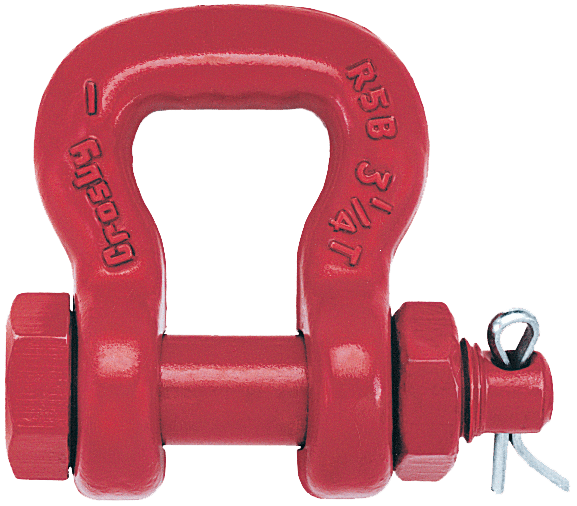

Crosby shackles stand out for their high quality, superior load rating, heat-treated alloy construction, and full traceability. Each shackle is marked with the Crosby name, working load limit (WLL), and size to ensure proper identification and safety compliance. Crosby offers several types of shackles for overhead lifting, including anchor (bow) shackles and chain (D) shackles, each available with screw pin, round pin, or bolt-type configurations. Common Crosby models include the G-209 and G-2130 Carbon Shackles, and G-213 and G-2140 Alloy Shackles, designed for rated overhead lifting applications.

Because of their consistent quality and adherence to ASME B30.26 and other industry standards, Crosby shackles are trusted worldwide in construction, offshore, and industrial lifting operations.

How do Crosby shackles compare to other brands?

Crosby shackles are widely regarded as the industry standard for quality, strength, and safety in rigging and lifting applications. Compared to other brands, Crosby shackles stand out due to their use of high-quality raw materials, precise forging processes, full traceability, and individual proof testing on specific model shackles. Each shackle is heat-treated and permanently marked with size, working load limit, and batch code, ensuring compliance with ASME B30.26 standard. While many lower-cost brands offer similar styles, they often lack the same level of quality control, documentation, and consistency in material strength. Although Crosby shackles typically cost more upfront, their reliability, durability, and proven performance make them the preferred choice for overhead lifting, construction, and critical load applications where failure is not an option.

Can you side load a Crosby shackle?

Crosby shackles are designed primarily for straight-line loading, but they can be side loaded within specific limits outlined by the manufacturer. According to Crosby’s guidelines, side loading should be minimized whenever possible, as it significantly reduces the shackle’s working load limit (WLL). When side loading cannot be avoided, the load should never exceed 50% of the rated WLL. The shackle pin should always be properly seated and secured, and the load should bear evenly across the bow, not the threads. For multi-leg sling setups where angular loading is unavoidable, always attach legs to the bow of the shackle with the pin up. For better D/d ratio use a Crosby Wide Body Shackle.

Where are Crosby shackles made?

Most Crosby shackles are manufactured in the United States at their Texas facility, using domestic-steel billets and a process of forging, heat treatment, machining and proof-testing. While Crosby is a global manufacturer, their Longview, TX facility is where a major portion of their shackle production takes place.