SYNTHETIC WEB SLING SAFETY BULLETIN

The following six points briefly summarize some important safety issues:

1 All users must be trained in sling selection (including limitations), use and inspection, hazards to personnel, environmental effects, and rigging practices. Users must know and follow all applicable standards and regulations.

2 Inspect sling for damage before each use. If the sling is damaged, IMMEDIATELY remove it from service.

3 Protect sling from damage. ALWAYS protect slings in contact with edges, corners, protrusions, or abrasive surfaces with materials of sufficient strength, thickness, and construction to prevent damage.

4 Do not exceed a sling’s rated capacity. Always consider the effect of sling angle and tension on the sling’s capacity and NEVER OVERLOAD web slings.

5 Do not stand on, under or near a load with the sling under tension. Any unplanned release of tension could drop the load and/or strike personnel with deadly recoil force. Be alert in the “danger zone” (area under or near the load, in-line or near slings under tension, etc.)

6 Maintain and store slings properly. Slings should be protected from UV light degradation, as well as from heat, chemical, environmental and/or mechanical damage.

1. All Sling Users Must be Trained and Knowledgeable

All web sling users must be trained on the proper use of web slings. The American Society of Mechanical Engineers standard for sling safety (ASME B30.9) states:

“Synthetic webbing sling users shall be trained in the selection, inspection, cautions to personnel, effects of the environment, and rigging practices as covered” by Chapter 9-5.

OSHA Guidance on Safe Sling Use (29 CFR 1910.184) states that a “qualified person” is one:

“who, by possession of a recognized degree or certificate of professional standing in an applicable field, or who, by extensive knowledge, training, and experience, has successfully demonstrated the ability to solve or resolve problems relating to the subject matter and work.”

It is important that all sling users be knowledgeable about the safe and proper use and application of slings (including the limitations of each sling type) and be thoroughly familiar with the manufacturer’s use and safety materials provided with each product. In addition, all sling users need to be aware of their responsibilities as outlined in all applicable standards (e.g., WSTDA WS-1 and WS-2; ASME B30) as well as all applicable provincial, state, federal, and OSHA regulations.

If you are unsure whether you have been properly trained, or if you are unsure of what the standards and regulations require of you, ask your employer for information and/or training—DO NOT use web slings until you are absolutely sure of what you are doing. Remember, when it comes to using web slings, lack of skill, knowledge and care can result in SEVERE INJURY or DEATH to you and others.

2. Slings Must Be Regularly and Properly Inspected

Even seemingly “minor” damage to a web sling can significantly reduce its capacity to hold or lift objects and increases the chance that the sling will fail during use. For example, one sling manufacturer has shown that a 3/8” cut (much smaller than the cut shown in Table 2) caused a sling to break under load at almost half its non-damaged capacity. Therefore, it is very important that web slings are regularly and properly inspected. If you are not sure whether a sling is damaged, DO NOT USE IT.

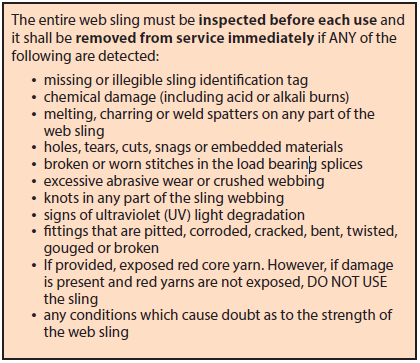

2a. How to inspect slings

To detect possible damage, you should perform a visual inspection of the entire sling and also feel along its entire length, as some damage may be felt more than seen. You should look and feel for any of the types of conditions listed in Table 1. Table 2 shows examples of some of these types of damage, but note that they are relatively extreme examples provided for illustration purposes only.

2b. What to do if you identify damage in a sling

If you identify ANY of these types of damage in a sling, remove it from service immediately even if the damage you feel or see is not as extensive as shown in the pictures in Table 2. Slings that are removed from service must be destroyed and rendered completely unusable unless they can be repaired and proof-tested by the sling’s manufacturer or other qualified person. You must never ignore sling damage or attempt to perform temporary field repairs of damaged slings (e.g., tie knots in the webbing, etc.).

Table 1. Web sling inspection – Removal criteria

2c. How often to inspect slings?

A three-stage procedure is recommended to help ensure that web slings are inspected with appropriate frequency:

Initial Inspection—Whenever a sling is initially received, it must be inspected by a qualified person to help ensure that the correct web sling has been received and is undamaged, and that the web sling meets applicable requirements for its intended use.

Frequent Inspection—Slings must be inspected by the sling user before each use.

Periodic Inspection—Every sling must be inspected “periodically” by a qualified person. In order to validate the frequent level of inspection, the periodic inspection should be performed by someone other than the individual(s) that most commonly performs the frequent inspection. The frequency of periodic inspections is based on the sling’s actual or expected frequency of use, severity of service conditions, the nature of the work performed with the sling, and experience gained during the inspection of other slings used in similar circumstances. Periodic inspections intervals must not exceed one year.

General guidelines for the frequency of periodic inspections are:

- Normal service—yearly

- Severe service—monthly to quarterly

- Special service—as recommended by a qualified person

Written records documenting the condition of individual slings are not required for frequent inspections. WSTDA WS-1 and ASME B30.9 require that a written record be maintained documenting when the most recent periodic inspection was performed. If a sling has been idle or in storage for more than 1 year since the last periodic inspection, prior to use the sling must be thoroughly inspected by a qualified person per the requirements for periodic inspection – maintain documentation that this inspection was performed. See WSTDA WS-1 for more information about definitions of Normal, Severe, and Special service conditions.

3. Slings Must be Adequately Protected from Damage

3a. Avoid environmental degradation

Environmental factors such as an exposure to sunlight, dirt or gritty-type matter, and cyclical changes in temperature and humidity, can result in an accelerated deterioration of web slings. The rate of this deterioration will vary with the level of exposure to these conditions, and with the thickness of the sling material. For example, single ply slings will generally degrade more rapidly with this exposure than multiple ply slings. Web slings that are used outdoors regularly should generally be permanently removed from service within a period of 2 to 4 years. All web slings that are exposed to these conditions should be highly scrutinized during their inspections. Visible indications of such deterioration can include the following:

- fading of webbing color

- uneven or disoriented surface yarn of the webbing

- shortening of the sling length

- reduction in elasticity and strength of the sling material due to an exposure to sunlight, often evident by an accelerated abrasive damage to the surface yarn of the sling

- breakage or damage to yarn fibers, often evident by a fuzzy appearance of the web

- stiffening of the web, which can become particularly evident when web slings are exposed to outdoor conditions without being used, or cyclically tensioned

3b. Avoid actions that cause damage to slings

You should always avoid any action that causes the types of damage identified in Section 2 of this Safety Bulletin, including (but not limited to):

- dropping or dragging slings on the ground, floor or over abrasive surfaces

- pulling slings from under loads when the load is resting on the sling—place blocks under load if feasible

- shortening or adjusting slings using methods not approved by the sling manufacturer or qualified person

- twisting, kinking, or knotting the sling

- exposing slings and fittings to damaging chemicals

- exposing slings to sources of heat damage or weld spatter

- using slings or allowing exposure to temperatures above 194°F (90°C) or below -40°F (-40°C)

- “tip loading” a sling on a hook instead of centering it in the base or “bowl” of the hook

- using hooks, shackles or other hardware that have edges or surfaces that could damage sling

- running/driving over slings with a vehicle/other equipment

You also need to select and use proper connection hardware with web slings to avoid damage.

Synthetic slings are affected by some chemicals ranging from little to total degradation. Time, temperature and concentration factors affect the degradation. For specific applications, consult the manufacturer. In addition, water absorption can decrease the strength of nylon web slings by as much as 10–15% (its strength returns when the sling dries completely). For specific applications, consult the manufacturer.

3c. Safeguard slings with sufficient protection

Synthetic web slings can be damaged, abraded or cut as tension and compression between the sling, the connection points and the load develops.

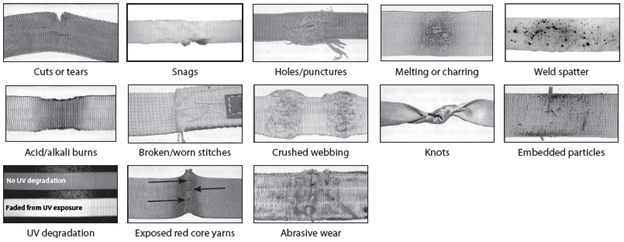

Table 2. Types of damage you should look and feel for in web slings.

Surfaces in contact with the sling do not have to be very abrasive or have “razor” sharp edges in order to create the conditions for sling failure. Therefore, web slings must ALWAYS be protected from being cut or damaged by corners, edges, protrusions or abrasive surfaces with protection sufficient for the intended purpose.

Abrasion protection will not prevent damage from cutting. If protection against cutting is necessary, use only sling protection that has been designed, tested, and rated by the manufacturer.

There are a variety of types of ways to protect slings from damage. A qualified person might select and use appropriate engineered sling protection (e.g., sleeves, pads, corner protectors, etc.) specifically designed to protect slings from damage.

Regardless of the particular method chosen:

- The goal is to ensure that the sling maintains its ability to securely lift the load while avoiding contact with damaging or abrasive surfaces under load.

- A qualified person must ensure that the protection method chosen is appropriate for the types of damage to which the slings will be exposed.

The protection used must not be makeshift (i.e., selecting and using cardboard, work gloves, or other such items based solely on convenience or availability).

Several “test” lifts, done in a non-consequence setting, may be necessary to determine the suitability of the protection device(s). After each “test” lift, the protection device(s) and sling(s) need to be inspected for damage and suitability. You should keep in mind that no protection is “cut proof” and you should always operate within the specified limits of the sling and its accessories (e.g., hardware, sling protection, etc.).

4. Always Use Slings Properly

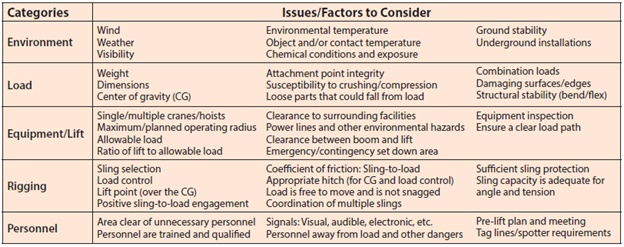

When handling loads, a trained, qualified and knowledgeable user must take into account all risk factors and issues addressed in this bulletin, as well as considering any other relevant factors that may be appropriate. For web slings, users must perform several activities, including (but not limited to) those discussed in the following subsections. Table 4 provides some, but not all, the factors that must be considered for successful load handling – also refer to ASME P30, ASME B30.9, WSTDA WS-1 and WS-2 for additional information.

4a. Assess the load

Determine the weight of the load (and, if more than one sling is used, the share of the load on each sling) and make sure it does not exceed the rated capacity of any sling or any of the components of the rigging system. Users must also determine the load’s center of gravity (CG) to make sure the rigging system used will be able to retain and control the load once lifted. When multiple slings and/or multiple leg bridles are used with non-symmetrical loads, an analysis by a qualified person should be done to prevent overloading of any sling and/or leg.

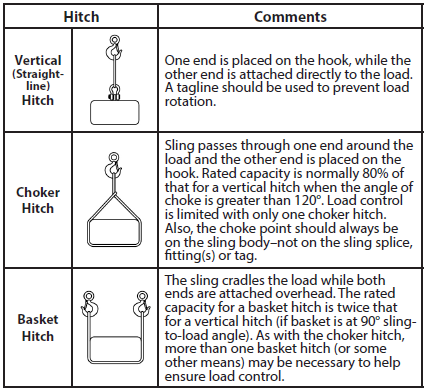

4b. Select an appropriate sling/configuration

Select a sling having suitable characteristics for the type, size, and weight of the load, the share of the load, the type of hitch (see Table 3), and the environment. The sling must be securely attached to the load and rigged in a manner to provide for load control to prevent slipping, sliding, and/or loss of the load. Always consider the effect of sling angle and tension on the sling’s capacity and ensure that the sling will not be loaded beyond its rated capacity. A trained, qualified, and knowledgeable user must determine the most appropriate method of rigging to help ensure a safe lift and control of the load.

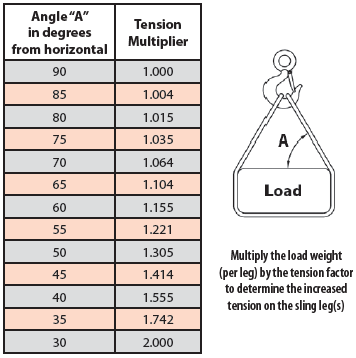

Another important consideration is the sling-to-load angle—the angle between a horizontal line and the sling leg or body. This angle is very important and can have a dramatic effect on the rated capacity of the sling. When the sling-to-load angle deviates from 90°, the tension on each leg increases.

Table 3. Common types of sling hitches

Table 4. Issues/factors to consider for safe load handling.

This principle applies in a number of conditions, including when one sling is used to lift at an angle and when a basket hitch or multi-legged bridle sling is used. Table 5 provides information about increased tension as a function of sling-to-load angle (assuming equally-loaded sling legs). Sling angles of less than 30 degrees are not recommended.

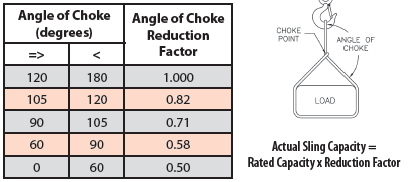

Similarly, when the angle of choke is less than 120 degrees, the sling choker hitch capacity decreases. To determine the actual sling capacity at a given angle of choke, multiply the sling capacity rating (for a choker hitch) by the appropriate Angle of Choke Reduction Factor determined from Table 6.

Nylon and polyester web slings elongate at different rates when under tension. Slings of different materials must not be used together during load handling activities.

4c. NEVER shock load or misuse slings and rigging

NEVER shock load the sling or the rigging (i.e., accelerate/decelerate the load too quickly). Working load limits are based on moderately dynamic lifting or load-handling activities. Instantaneous changes (rapid acceleration or sudden stops) constitute hazardous shock loading which may overload the sling leading to sling failure, the unplanned release of tension and/or loss of load control. SEVERE INJURY or DEATH and/or property damage are potential outcomes of shock loading.

NEVER misuse slings and rigging:

- NEVER pull on stuck, snagged, or restrained objects (load-measuring devices/methods must be used to ensure overloading never occurs).

- NEVER use slings for towing purposes.

A web sling should only be used for load handling.

5. Make Sure All Personnel are Clear of Loads and Alert to Risks, Especially in the “Danger Zone”

Even if you account for all of the factors/issues discussed in this Safety Bulletin, things can still go wrong. Therefore, all personnel must be alert to potential risks associated with the use of web slings, especially in the “Danger Zone.” The “Danger Zone” is any area where (a) the load could fall on or swing into personnel or property, or (b) deadly recoil could be produced by an unplanned release of tension. Therefore:

- All personnel must stand clear of lifted loads and never be under, on, or near suspended loads.

- Personnel must not stand in-line with or next to rigging under tension. Any unplanned release of tension could strike personnel with deadly recoil force.

- Personnel must be alert to the potential for the sling and/or load to become snagged/hung-up during load handling.

- Once load-handling activities begin, sling users must NEVER place any part of the body between the sling and the load or between the sling and hook/shackle/connection point and/or load-handling device.

- Personnel must never ride the sling or load.

6. Properly Maintain and Store Slings

Slings should be protected from UV light degradation, as well as from heat, chemical, environmental and/or mechanical damage. In order to prevent damage to slings, especially when not in use:

- store slings in a cool, dry and dark location to protect against UV light degradation and heat damage

- store slings in an area free from environmental, chemical, or mechanical sources of damage (e.g., weld spatter, splinters from grinding or machining, heat sources, etc.)

Do not scrub or wash web slings, as a loss of strength is possible due to mechanical/chemical damage. Wet slings should be allowed to dry before being stored.

Table 5. Increased sling tension as a function

of sling-to-load angle

Table 6. Reductions in rated capacity

as a function of angle of choke

NEVER ON. NEVER UNDER. NEVER IN-LINE.