SPARKEATER® HIGH TEMPERATURE ROUNDSLINGS

Sparkeater Roundsling (TPSE)

The Sparkeater sling is a flexible, lightweight roundsling specially designed to work in hot environments. The Sparkeater round sling easily replaces heavy wire rope and chain slings and provides the user with a significantly lighter, more ergonomic product with many of the same features as the trusted Twin-Path® Sling.

The Sparkeater sling cover and internal load bearing core yarns are made of high heat-resistant fibers. This enables the Sparkeater sling to work in extreme temperatures while maximizing productivity by decreasing operator fatigue and workplace injuries.

FEATURES

High Heat

Repairable

Twin-Path

Lightweight

Check-Fast

Flexible

Low Stretch

Low Length Tolerance

Proof Tested

TWIN-PATH SLINGS

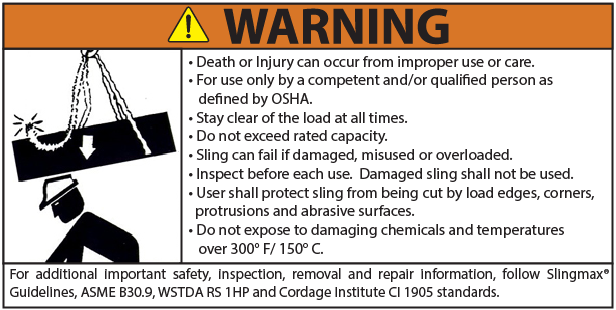

USE AND CARE

CUT PROTECTION

High-Temperature Roundsling

The Sparkeater sling is designed to withstand heat up to 300°F or 150°C with no loss in strength. The Sparkeater high-temperature lifting sling includes unique safety features not found in any other rigging designed for high-temperature applications. The two separate paths of load bearing core fibers add redundancy to your roundsling, ensuring that if damage occurs to one path, the crane operator can safely lower the load to the ground for inspection.

The Sparkeater sling includes a double cover (yellow outer cover and red inner cover) which provides a method to easily identify abrasion damage to the cover before it affects the load bearing core yarn. If the outer cover becomes damaged the sling can be returned, evaluated and repaired. Every repaired sling is inspected, tested and recertified.

Check-Fast® Inspection System

All Sparkeater Slings come equipped with the Check-Fast inspection system, the most tested and reliable sling overload indicator available. The Check-Fast External Warning Indicator (EWI) provides a criteria for pass/fail inspection when the internal load-bearing core yarn may have been subjected to conditions outside of the slings rated capacity. If the sling is overloaded beyond its rated capacity, the EWI is designed to retract inside of the sling jacket before the sling fails. This provides the sling inspector an additional, objective “GO/NO-GO” inspection device rather than only relying on subjective and labor-intensive inspection techniques.