Ultrex: Premium 12-Strand Dyneema® Rope

Ultrex is a high-performance 12-strand single braid rope proudly manufactured in the USA by Yale Cordage. Constructed from Dyneema® (HMPE) fiber and protected with Maxijacket HP, a heavy-duty coating designed for exceptional abrasion resistance. Ultrex is built to withstand demanding applications while maintaining strength and flexibility.

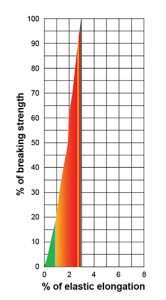

Designed with optimized braid angles and precise twist configurations, Ultrex delivers impressive tensile strength and minimal stretch, making it ideal for professionals who need reliability and performance in the field.

Key Features:

-

Exceptionally low stretch under load

-

Will not absorb water

-

Lightweight—can be deployed via helicopter

-

Maxijacket HP coating delivers outstanding abrasion protection

-

Remains flexible even in sub-zero temperatures

-

Extremely high strength-to-weight ratio

-

Long-lasting durability under repeated use

-

Easy to splice and handle

-

Made in the USA using genuine Dyneema fiber

The Dyneema HMPE fiber used in Ultrex is produced domestically by Avient. Known for its superior fatigue and bending endurance, Dyneema offers better sheave cycling performance than other high-modulus fibers. With zero water uptake and reliable performance in cold environments, Ultrex is engineered to excel in even the harshest conditions.

Note: Published strength ratings reflect spliced configurations.

How It’s Made:

How to Buy

Ultrex Splicing Instructions

Approved Splice Technique: #10015112, #10018009.

High Performance Single Braid – Eye Splice

High Performance Single Braid – End for End Splice

Ultrex Specifications and Data

| Diameter (Inches) | Weight (Lbs/100f) | Average Spliced Break Strength *(Lbs) | Minimum Spliced Break Strength *(Lbs) | Maximum Working Load 5:1 **(Lbs) |

| 1/16 | 0.1 | 800 | 720 | 160 |

| 1/8 | 0.3 | 2,200 | 1,980 | 440 |

| 5/32 | 0.5 | 3,400 | 3,060 | 680 |

| 3/16 | 1.0 | 6,000 | 5,400 | 1,200 |

| 1/4 | 1.7 | 10,000 | 9,000 | 2,000 |

| 5/16 | 2.4 | 14,800 | 13,320 | 2,960 |

| 3/8 | 3.6 | 20,000 | 18,000 | 4,000 |

| 7/16 | 4.6 | 26,500 | 23,850 | 5,300 |

| 1/2 | 6.4 | 37,400 | 33,660 | 7,480 |

| 9/16 | 8.0 | 45,000 | 40,500 | 9,000 |

| 5/8 | 9.5 | 53,000 | 47,700 | 10,600 |

| 3/4 | 14.0 | 75,000 | 67,500 | 15,000 |

| 7/8 | 17.9 | 98,000 | 88,200 | 19,600 |

| 1 | 24.2 | 120,000 | 108,000 | 24,000 |

| 1-1/8 | 28.8 | 148,000 | 133,200 | 29,600 |

| 1-1/4 | 33.9 | 172,000 | 154,800 | 34,400 |

| 1-5/16 | 41.8 | 184,000 | 165,600 | 36,800 |

| 1-1/2 | 55.4 | 254,000 | 229,320 | 50,800 |

| Diameter (mm) | Weight (Kg/100m) | Average Spliced Break Strength *(kg) | Minimum Spliced Break Strength *(kg) | Maximum Working Load 5:1 **(kg) |

| 2 | 0.2 | 360 | 324 | 72 |

| 3 | 0.5 | 995 | 896 | 199 |

| 4 | 0.8 | 1,540 | 1,386 | 308 |

| 5 | 1.5 | 2,720 | 2,448 | 544 |

| 6 | 2.5 | 4,540 | 4,086 | 908 |

| 8 | 3.6 | 6,715 | 6,044 | 1,343 |

| 10 | 5.3 | 9,080 | 8,172 | 1,816 |

| 11 | 6.8 | 12,030 | 10,827 | 2,406 |

| 13 | 9.6 | 16,975 | 15,278 | 3,395 |

| 14 | 11.9 | 20,430 | 18,387 | 4,086 |

| 16 | 14.1 | 24,060 | 21,654 | 4,812 |

| 19 | 20.8 | 34,050 | 30,645 | 6,810 |

| 22 | 26.7 | 44,490 | 40,041 | 8,898 |

| 25 | 36.0 | 54,480 | 49,032 | 10,896 |

| 29 | 42.9 | 67,190 | 60,471 | 13,438 |

| 32 | 50.5 | 78,085 | 70,277 | 15,617 |

| 33 | 62.2 | 83,535 | 75,182 | 16,707 |

| 38 | 82.5 | 115,675 | 104,108 | 23,042 |

* Knots and abrupt bends significantly reduce the strength of all ropes and lower the maximum working load.

** Working load is based on static or moderately dynamic lifting/pulling operations. Instantaneous changes in load, up or down, in excess of 10% of the rope’s rated working load constitute hazardous shock load and would void the normal working-load recommendation. Consult Yale Cordage for guidelines for working loads and the safe use of rope.

Specific Gravity: 0.97

Dielectric Strength: The maximum allowable leakage for clean, dry Ultrex is 75 micro-amperes when tested at 100kV per Yale Method 712-1701 Rev 1 “Routine Production Test.” Absorbed and entrained moisture or impurities will increase the rope’s conductivity dramatically.