Modernizing Utility Stringing Line Inspections: How AI Technology is Redefining Safety and Reliability

Utility companies are tasked with maintaining grid reliability — a complex responsibility given aging country-wide infrastructure, much of which was built in the mid-20th century. As of 2023, 70% of lines and transformers deployed on the grid were over 25 years old. At the same time, crews must perform their work faster and more safely than ever before. The stakes are high: a single line failure during stringing can halt a project, damage costly equipment, and put lives at risk.

Traditionally, stringing-line inspections have relied on time-consuming manual methods. Technicians inspect miles of stringing line, visually searching for abrasion, cuts, or fatigue — issues that can be easily missed in poor lighting, environments lacking a 360-degree view, or inspector fatigue. These limitations have driven the need for more advanced, data-driven approaches.

That’s where Scope® Inspection Technology, available through I&I Sling’s Greensboro, NC facility, comes in. In partnership with Yale Cordage, the leader in high-performance synthetic rope manufacturing, I&I Sling now offers utilities and contractors a next-generation way to assess, document, and maintain their stringing lines with unmatched accuracy and speed.

Understanding Utility Stringing

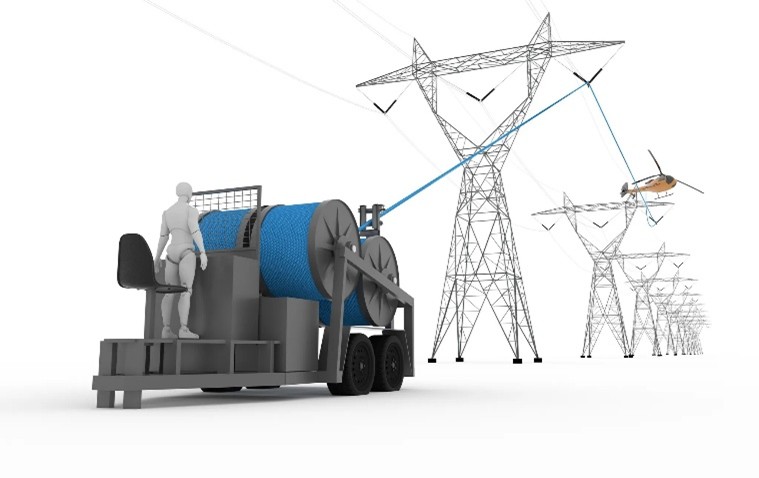

Utility line stringing is the process of installing overhead electrical conductors between towers for new line construction, reconductoring operations, hardening & resiliency projects— one of the most demanding phases in building or upgrading transmission and distribution infrastructure.

Key stages include:

- Pulling Line Setup: A lightweight pilot line is installed and then progressively replaced by stronger ropes until the conductor is ready to be pulled.

- Conductor Installation: Specialized pullers and tensioners gradually feed the conductor into place, maintaining precise tension to prevent damage or sagging.

- Final Sagging and Clipping: Crews tension and secure conductors to meet design specifications adjusted for temperature and load.

Each phase depends on the reliability of synthetic stringing lines — which means inspection and maintenance are essential.

The Hidden Hazards of Stringing Operations

Stringing operations involve multiple hazards that demand proactive risk management:

- Line Failure and Snap-Back: A rope under thousands of pounds of tension can recoil violently if it fails, creating severe injury or fatality risks.

- Electrical Exposure: Unintentional contact with energized conductors can cause electric shock or arc flash events.

- Height and Fall Risks: Crews working on towers or elevated platforms face continuous exposure to fall hazards.

- Environmental and Terrain Challenges: Uneven terrain, road crossings, and public spaces add complexity and public-safety considerations.

Each of these risks is amplified if the pulling line itself is compromised.

Why Line Inspections Matter

Routine inspections are central to maintaining both grid reliability and worksite safety. Proper line care supports:

- Preventive Maintenance: Early detection of abrasion or fatigue avoids dangerous catastrophic failures.

- Regulatory Compliance: Utilities must meet OSHA and NESC standards with verifiable inspection documentation.

- Asset Reliability: Inspections reduce outages, extend rope life, and improve fleet performance.

But as demand for construction and maintenance rises, so does scrutiny from regulators, investors, and the public. Utilities are under pressure to prove that every component — down to each stringing line — is inspected, documented, and safe.

The Cost of a Stringing Line Failure

A single rope failure can trigger cascading consequences across an organization:

-

Safety Executive

-

Primary Responsibility: Protect workers and uphold safety culture

-

Impact of Line Failure: Severe injury, OSHA investigation, reputational harm, loss of crew trust

-

-

T&D Executive

-

Primary Responsibility: Deliver compliant builds on schedule

-

Impact of Line Failure: Delays, cost overruns, rework, QA/QC non-conformance

-

-

Operations Executive

-

Primary Responsibility: Maintain crew efficiency and uptime

-

Impact of Line Failure: Equipment damage, idle labor, schedule disruptions

-

-

Fleet Executive

-

Primary Responsibility: Preserve equipment integrity

-

Impact of Line Failure: Accelerated wear, unplanned repairs, inventory depletion

-

These risks underscore the importance of precision-driven inspection technology that can identify weak points before they fail.

Enter Scope: The Future of Stringing Line Inspections

Scope is an AI-powered inspection system engineered specifically for synthetic stringing lines. Rather than replacing certified inspectors, it amplifies their capabilities — giving them real-time insights into rope condition, strength, and safety.

At I&I Sling, the Scope system is integrated into our inspection workflow to support synthetic ropes used throughout the electrical-utility sector. Together, this partnership ensures that every line not only meets but exceeds the highest safety and performance standards.

How the Scope System Works

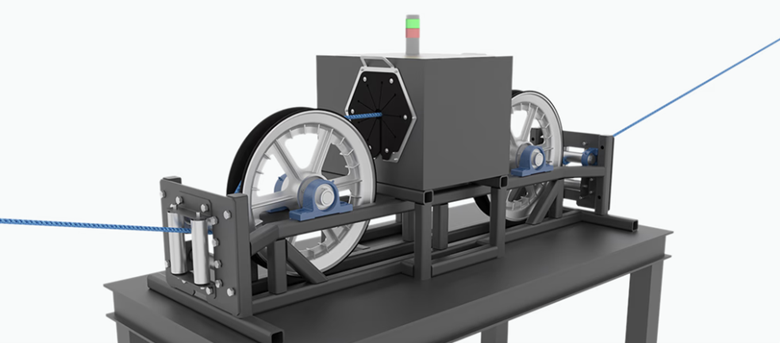

- Setup & Positioning

The operator mounts the rope on a powered reel system that feeds through the Scope inspection unit at a steady 4 mph. Proper line tension and spacing ensure accurate image capture. - 360° Data Capture

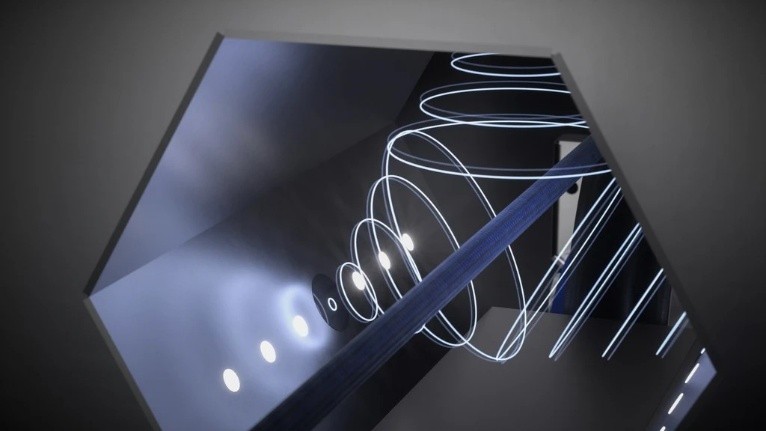

Cameras inside the device photograph the line every six inches — providing a complete circumferential view controlled by a magnetic rotary encoder for exact measurement. - Neural-Network Analysis

Two deep-learning models evaluate every segment: one predicts residual break strength; the other detects hazards such as cut strands, splices, and debris. Results appear in real-time on the operator’s tablet. - Repair & Verification Scans

If the system flags an issue, the rope can be repaired or spliced according to manufacturer specifications. Scope automatically cues the operator when the damaged section approaches for precise intervention. - Reporting & Certification

Once inspection is complete, the system generates a Line Certificate summarizing key data (date, inspector, rope ID, findings) and a Line Report containing imagery and decision history. These become part of the customer’s permanent maintenance record.

This workflow transforms what was once a manual, hours-long process into a precise, traceable inspection that can quickly cover thousands of feet of rope.

Equipment and Operational Requirements

For optimal performance, Scope inspections follow standard stringing-line setups:

- Reel Configuration: An inspection reel and a receiving reel spaced ~50 ft apart, with the Scope system centered between.

- Line Speed: Max 4 mph for accurate scanning.

- Internet Connectivity: A stable Wi-Fi or cellular signal ensures real-time data transfer and cloud documentation.

- Splicing Capabilities: Damaged segments can be spliced following manufacturer-approved methods — for example, direct-bury splices for 12-strand ropes. Certified splicer training is strongly recommended annually.

Inventory readiness is equally crucial: keeping replacement ropes on hand that match in construction, color, and performance ensures minimal downtime during repairs.

What the System Does — and Doesn’t

Scope enhances, but does not replace, the certified inspector. Human expertise remains essential for evaluating context, verifying repairs, and approving final line integrity.

Scope cannot:

- Accurately inspect ropes outside its trained product models.

- Analyze lines that are completely concealed by debris or mud.

- Operate offline without stable connectivity.

Its true strength lies in its partnership with human judgment — providing inspectors with pinpoint data to make smarter, faster, safer decisions.

Why This Matters to Today’s Utilities

America’s electric grid spans more than 200,000 miles of high-voltage lines — many nearing or exceeding their intended lifespan. Modernization efforts are accelerating as utilities integrate renewable generation, electrify transportation, and harden systems against extreme weather. Microsoft and Google project the U.S. will need an additional 500,000 electricians over the next decade to keep up increasing energy consumption.

In this new era, data-driven maintenance is not a luxury; it’s a requirement. Technologies like Scope give utilities and contractors the ability to:

- Validate safety with verifiable inspection records.

- Reduce downtime by identifying damage before failure.

- Extend rope life through targeted repairs instead of full replacements.

- Support compliance with clear, time-stamped documentation.

For large utility contractors and fleet managers, these benefits translate into fewer disruptions, lower lifecycle costs, and a stronger safety culture.

The Partnership Behind the Technology

I&I Sling brings decades of rigging and lifting expertise to the electrical-utility sector. As a Slingmax®

Rigging Solutions manufacturer and Yale Cordage distributor, I&I Sling is uniquely positioned to provide complete life-cycle support — from supplying industry-leading stringing lines to maintaining them with cutting-edge inspection tools.

A Safer, Smarter Future for Utility Stringing

As utility networks grow in scale and complexity, inspection technology must keep pace. The integration of Scope into I&I Sling’s service lineup represents a decisive step toward that future — one where AI and human expertise combine to deliver faster, safer, and more reliable results.

Whether you’re a utility company managing fleet assets or a contractor responsible for day-to-day line pulling, the message is clear: the tools for smarter inspections are here.

Contact I&I Sling to schedule a Scope inspection today and experience how AI-enhanced precision can elevate your stringing operations — from safety and compliance to long-term performance.