SLINGMAX® HELIX® ROUNDSLINGS

Helix High Performance Synthetic Roundslings

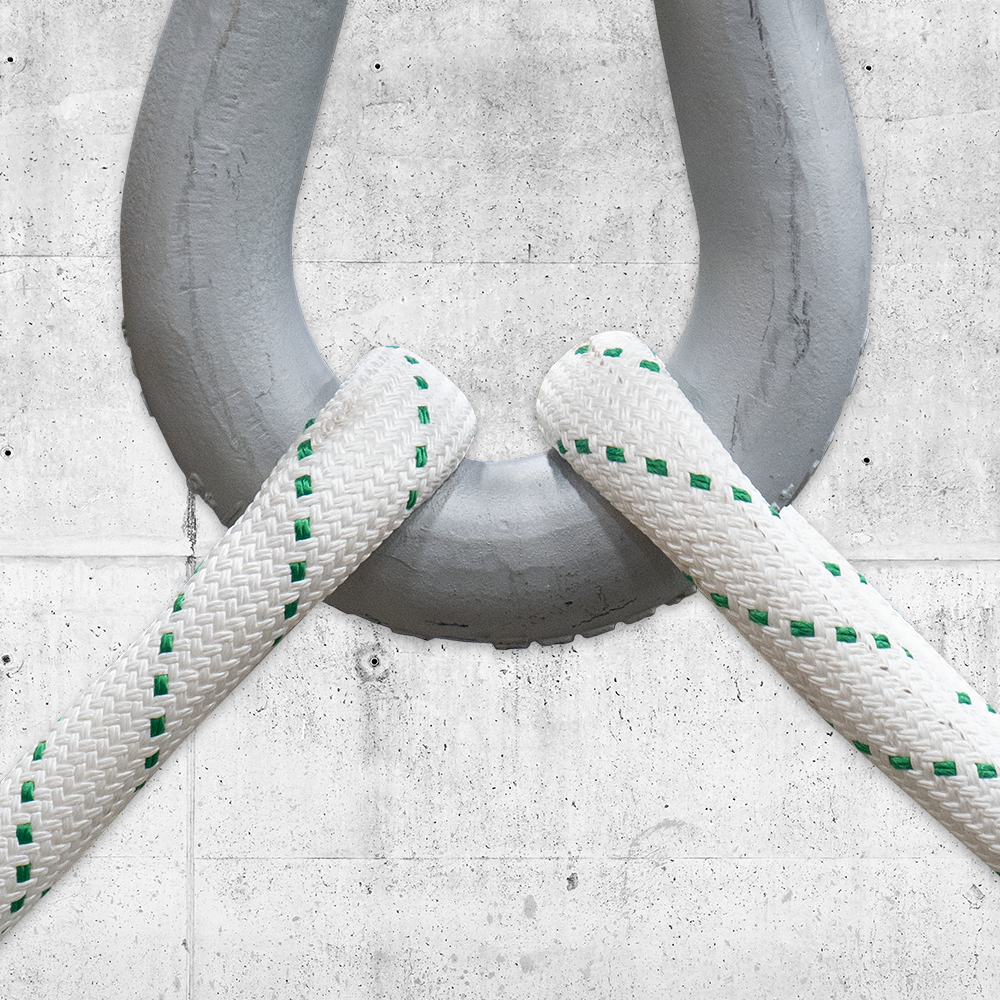

Helix Heavy Lift Slings are high-performance fiber roundslings designed with a narrow width, making them ideal for lifting operations involving restricted space, trunnions or narrow hardware. These slings feature K-Spec® core fiber, a highly trusted roundsling core yarn that has been refined specifically for overhead lifting applications for over 30 years. Known for its exceptional durability, strength, and lightweight properties, K-Spec offers less than 1% elongation at rated capacity. Helix slings are protected by an abrasion and chemical-resistant HMPE braided jacket that is crafted in the USA and incorporates Rifled Cover Technology to enhance strength by 17% while reducing both sling weight and width. This advanced design ensures high strength capacities while maintaining a streamlined profile, making the Helix sling the ideal solution for demanding lifting applications.

Manufactured on the Slingmax Roundsling machine by skilled Slingmax Dealers, Helix slings deliver consistent quality and reliability. The HMPE braided jacket provides excellent protection against minor jacket abrasion damage. Helix roundslings are compatible with the entire line of Slingmax's engineered edge and cut protection, such as the Cornermax Pad, Cornermax Sleeve, and Spider Sleeve.

I&I Sling is the premier manufacturer of Slingmax slings on the East Coast of the United States. We've been manufacturing synthetic roundslings since 1986 and continue to offer the latest in high-performance lifting solutions, including Helix.

FEATURES

Narrow Diameter Footprint

Long Lasting

Proof Tested

Braided HMPE Jacket

Lightweight

Rifled Cover Technology

Assembled in USA

K-Spec

High Capacity

TWIN-PATH ROUNDSLINGS

RIGGING HARDWARE

CUT PROTECTION

K-Spec Core Yarn

Inside every Slingmax Helix roundsling is multiple strands of K-Spec core yarn, a specialized blend of high-performance fibers meticulously crafted in North Carolina, USA. K-Spec core yarn has been refined over more than 30 years and designed specifically to enhance overhead lifting capabilities. The Helix Sling derives its name from its innovative design, which utilizes a tightly braided HMPE jacket woven in such a way that incorporates our patented Rifled Cover Technology which helically twists core yarn during the sling manufacturing process significantly boosting efficiency and reliability without adding extra weight. Because of this increase in efficiency paired with the braided HMPE jacket, Helix lifting slings have a narrow footprint, allowing them to be used in tight trunnion or lifting applications that require narrow hardware without the need to taper. K-Spec Core Yarn excels in yarn abrasion resistance and durability, maintaining strength and performance for up to 20 years when taken care of properly.

Our Relationship with Slingmax Rigging Solutions

I&I Sling has a long-standing history of producing high-performance roundslings, beginning with the pioneering Kevlar slings that quickly became a favorite among riggers for their exceptional strength and lightweight design. Building on this success, I&I Sling collaborated with Slingmax Rigging Solutions to develop cutting-edge synthetic lifting slings, setting new industry standards.

I&I Sling is the largest Slingmax dealer on the East Coast of the United States. Starting in 1977, I&I Sling was the first rigging supplier to fabricate and sell Slingmax wire rope designs, helping set the standard for the industry. In 1986, when Slingmax introduced the revolutionary Twin-Path roundsling, I&I Sling was at the forefront, producing the first high-performance synthetic roundslings for the heavy lifting sector. This partnership has solidified I&I Sling’s role as a crucial manufacturing dealer and strategic partner to the Slingmax Organization.

In addition to the renowned Twin-Path slings, I&I Sling now fabricates the advanced Helix slings. These state-of-the-art slings feature a braided HMPE jacket and K-Spec fibers, offering exceptional strength, durability, and a narrow diameter profile for easy handling in tight hardware and lifting points. Helix slings represent the latest innovation in I&I Sling’s commitment to providing the most advanced lifting solutions in the industry.

Today, all six I&I Sling branches are fully equipped with multiple Slingmax roundsling machines, enabling the production, inspection, and repair of thousands of Twin-Path and Helix slings annually. Some of the skilled fabricators at I&I Sling have been crafting Twin-Path slings since their inception over three decades ago, showcasing the company's deep expertise and commitment to quality.

Narrow Width Sling Profile

Helix slings are engineered to deliver high strength while maintaining a narrow width, making them ideal for lifting in spaces where traditional slings might be too bulky. This slim profile allows for efficient use with narrow hardware or in confined environments without sacrificing lifting capacity.

High Strength, Durability, Compact Design

Helix slings utilize K-Spec core fiber, known for its unmatched strength, durability, and minimal elongation of less than 1% at rated capacity. Precisely fabricated on the Slingmax roundsling machine enables Helix slings to have exceptional length tolerances for use as sets, ensuring consistent performance even under heavy loads