Crosby Sling Saver® Web Sling Shackles S-281

Crosby Sling Saver® S-281

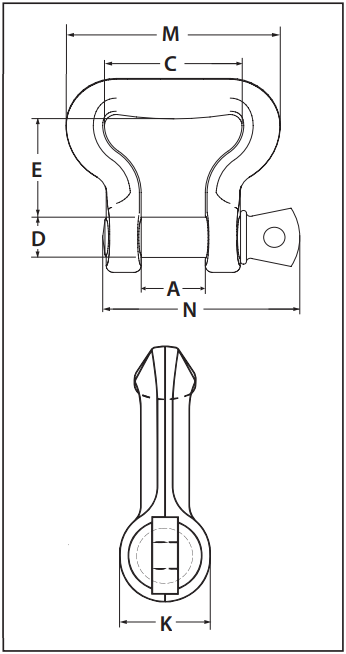

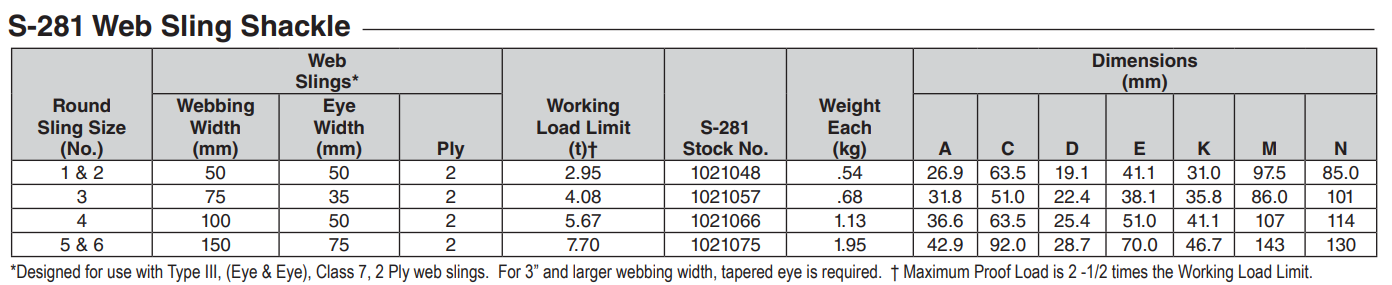

Crosby Sling Saver® Web Sling Shackle is designed to connect Synthetic Web Slings and Synthetic Round Slings to eyebolts, pad eyes, and lifting lugs.

- All Alloy Construction.

- Design Factor of 5:1.

- Each shackle has a Product Identification Code (PIC) for material traceability along with a Working Load Limit and the name Crosby forged into it.

- Incorporates same ear spread and pin dimensions as conventional Crosby Shackles. Allows easy connection to pad eyes, eye bolts, and lifting lugs.

- Increased radius of bow gives wider sling bearing surface resulting in an increased area for load distribution, thus:

- Increasing Synthetic Sling efficiency as compared to standard anchor and chain shackle bows and conventional eye hooks. This allows 100% of the sling's rated Working Load Limit to be achieved.

- Allows better load distribution on internal fibers.

- Meets or exceeds all requirements of ASME B30.26 including identification,

ductility, design factor, proof load and temperature requirements. Importantly, these shackles meet other critical performance requirements including fatigue life, impact properties and material traceability, not addressed by ASME B30.26. - Look for the Red Pin® ... The mark of genuine Crosby Shackle Quality

Web Slings vs. Roundslings

Web Slings are flexible, lightweight, and have a flat construction, normally with eyes at both ends. The flexibility of the sling helps to reduce shock loading effects. It is also important to note that the load-bearing yarns of the sling come in direct contact with the load. Roundslings, however, are a continuous loop of yarn covered by a woven tubular casing. This casing comes in direct contact with the load, which helps to protect the load-bearing yarns inside. Whether Web or Round, rest assured that the Crosby Sling Saver® product line offers the fitting you need to get the most out of your slings in the toughest lifting applications and environments.