Polydyne

Polydyne

Polydyne is a double-braided rope that utilizes a polyester sleeve over a nylon core. Despite the dissimilar stretch characteristics of these fibers, Yale engineers have produced constructions where both fibers contribute.

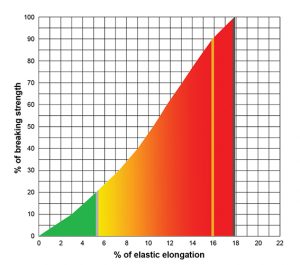

The resulting rope has high breaking strength and more stretch in its working load range, which in many applications is a plus. Polydyne is up to taking more dynamic abuse without being degraded prematurely. Take special note of the working energy-absorption rating, which is the amount of energy a rope absorbs before reaching its working load. The ultimate energy absorption of this rope is also correspondingly high. All this and a tough polyester jacket make this a long-wearing rope with extraordinary dynamic capabilities.

Polydyne Splicing Instructions

Approved Splice Technique: #10017200 (Industrial Double Braid Eye Splice).

Industrial Double Braid – Eye Splice

Polydyne Specifications and Data

* Knots and abrupt bends significantly reduce the strength of all ropes and lower the maximum working load.

** Working load is based on static or moderately dynamic lifting/pulling operations. Instantaneous changes in load, up or down, in excess of 10% of the rope’s rated working load constitute hazardous shock load and would void the normal working-load recommendation. Consult Yale Cordage for guidelines for working loads and the safe use of rope.

Specific Gravity: 1.24

Dielectric Strength: The maximum allowable leakage for clean, dry Polydyne is 500 micro-amperes when tested at 100kV per Yale Method 712-1701 Rev 1 "Routine Production Test." Absorbed and entrained moisture or impurities will increase rope’s conductivity dramatically.