SMART SLING

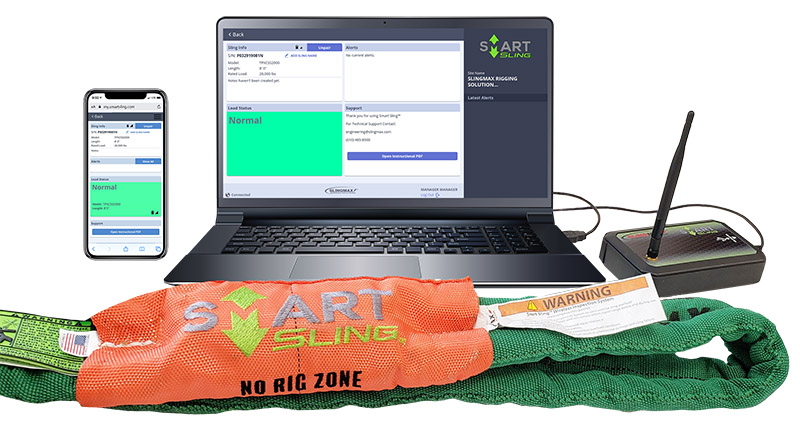

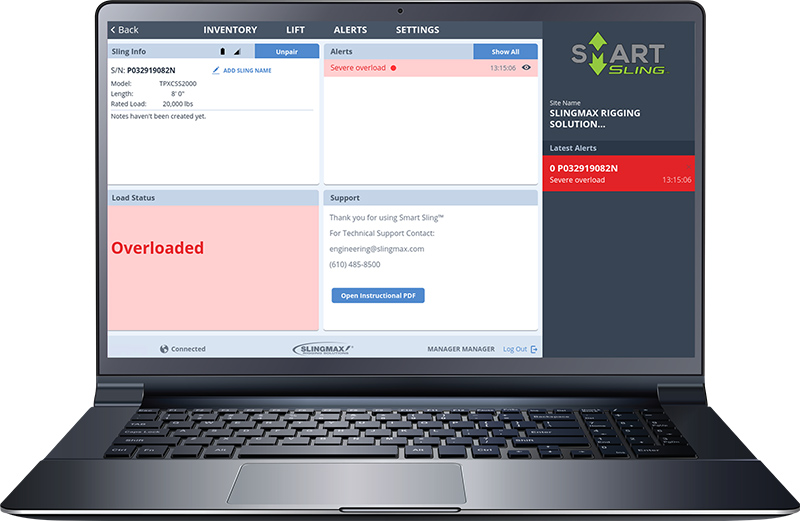

Planning and executing a critical lift is tough. Your crane is in position and it’s time to begin the lift – you need to know that every detail is going as planned and that your people are not in danger. Mistakes happen – loads shift, human error and shock loads occur. With Smart Sling, you can monitor your rigging in real time and you are immediately alerted to critical overloads that would otherwise endanger workers or cause a catastrophic accident.

Connect With Your Slings

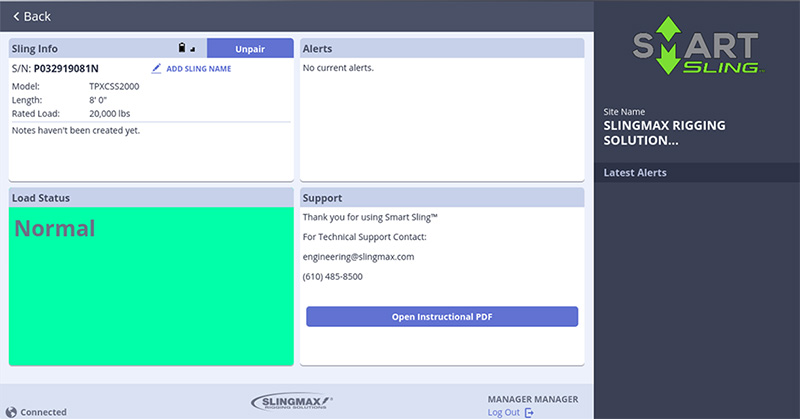

Smart Sling provides insight into your slings condition. If your Smart Sling is severely overloaded, all specified users will receive an alert. On site, or off site, smart sling will keep your team informed.

Ease of Use

Industrial Software does not need to be complicated. The Smart Sling software is built on a web based platform that is simple to use. Your Smart Slings can be monitored using any device.

Multiple Base Stations

Expand your system. One Smart Sling basestation monitors up to 50 slings with a range of 1000 feet. The Smart Sling system allows multiple basestation integrations to expand the range to fit your entire jobsite.

Alert History

Smart Sling creates a record of which slings may have been overloaded and adds a timestamp to that event. Notes can be added to keep all users informed of the sling status. Knowledge is power, and with Smart Sling your crew has the critical sling information they need to lift with a level of confidence not available before.

Keeping Lifts Simple

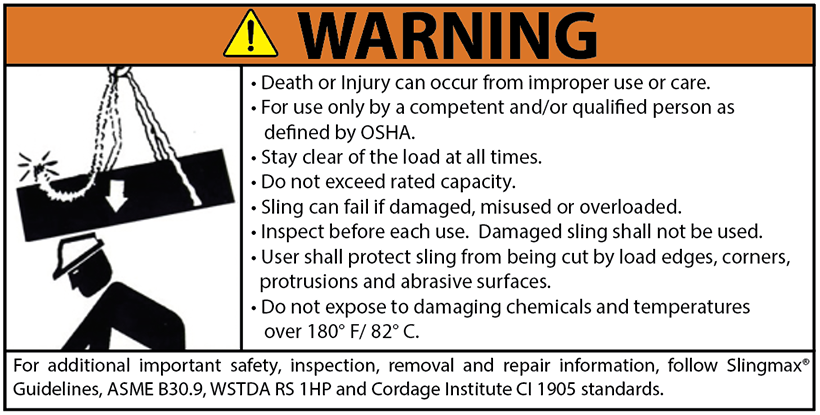

Every Smart Sling has an embedded Sling Overload Sensor that is always on and constantly monitoring the condition of the roundsling for overload. Each Sling Overload Sensor includes a 2 years always-on battery that does not require powering on or off. With Smart Sling, complicated external load measurement devices are no longer needed.